Services

Standard analysis

VDA 19.1 – ISO 16232

The first step in standard inspection analysis is the determination of the inspection procedure, as well as the limits and requirements to be evaluated. These limits can be usually found in the drawing. BIDEA LAB performs a technical study for each component specifically in response to each client enquiry.

Analysis performance

For the initial inspection of any sample component, a qualification test must first be carried out to define the reduction curve. After the initial test, provided that there are no changes in the test component at a constructional or production level, this qualification test will serve as the standard for subsequent routine tests. For the inspection itself, we use different extraction methodologies, including pressure rinsing, internal rinsing, agitation, ultrasound, air jet extraction, suction, customer specific methods, etc.

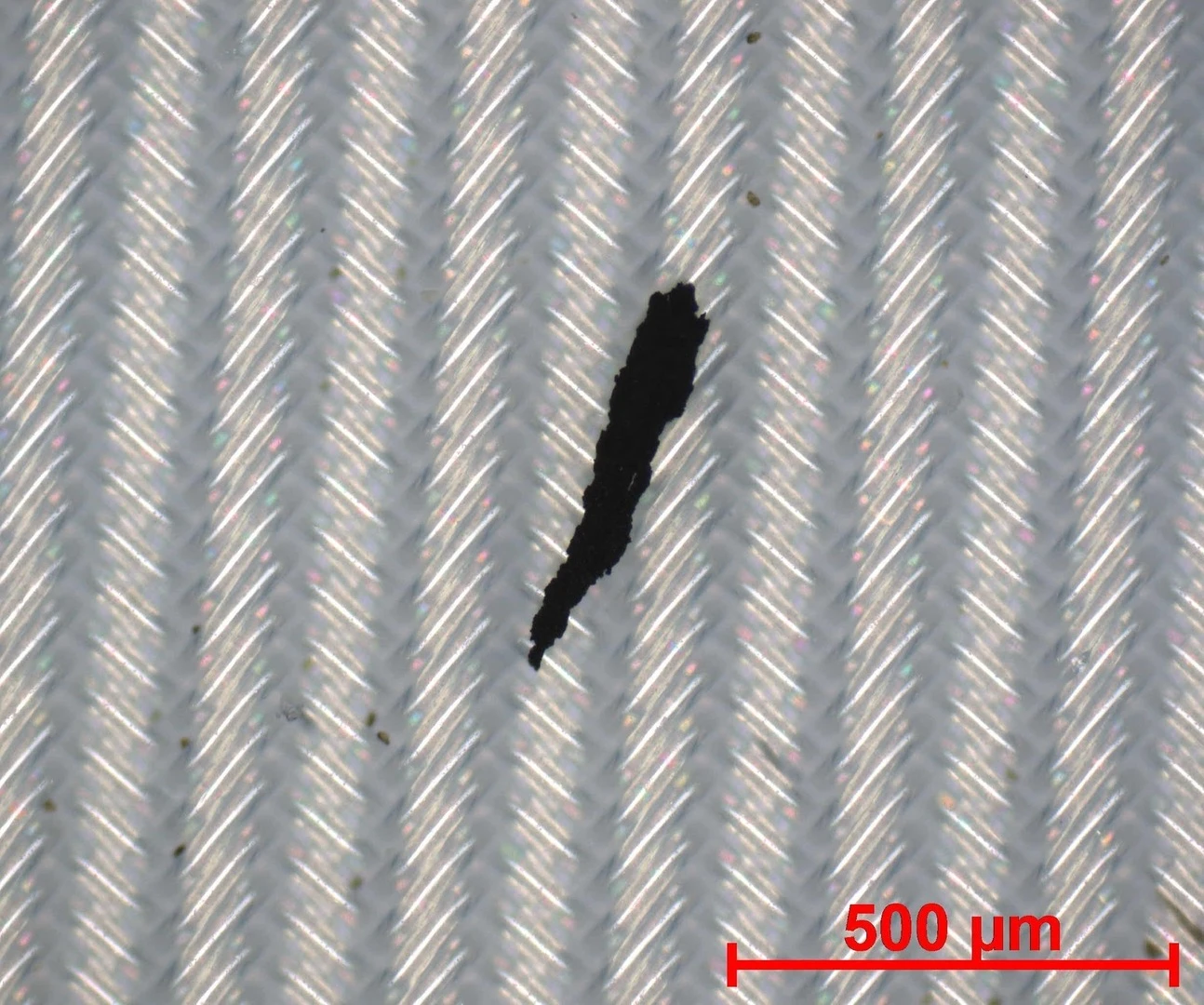

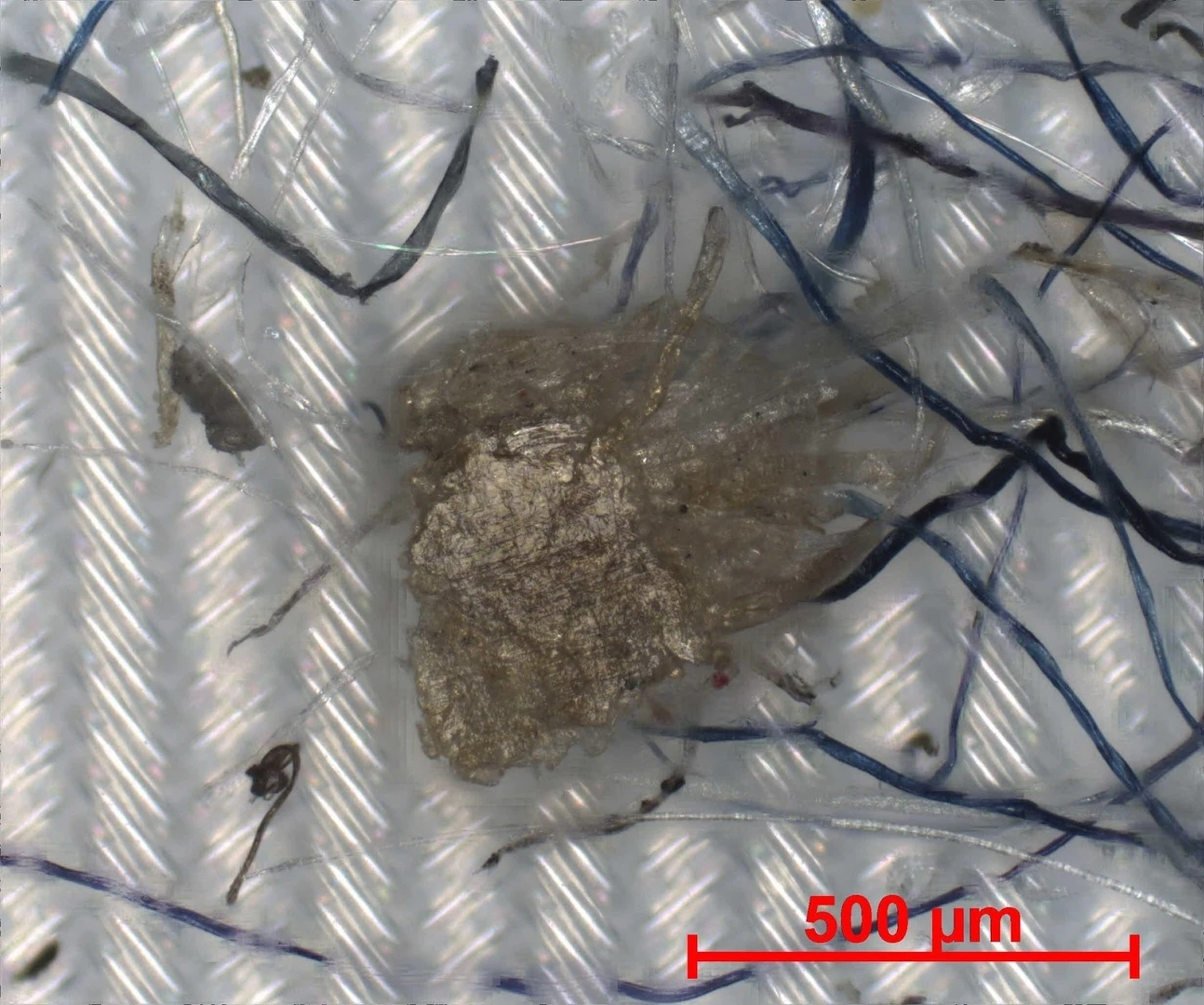

Contaminant particles separated on the analysis filters are optically measured, counted and classified as metallic or non-metallic by shiny-non shiny classification. In addition, it may be necessary to include a gravimetric evaluation of the residual weight of the total particulate mass.

Is your component too large? No problem. We can perform the extraction on site at your facilities.

Is your customer asking you to verify a specific standard or requirement to your product?

Application and Purpose:

Application and Purpose:

- Manufacturing industry in general.

- To determine particulate contamination / residual dirt on components after production.

- Evaluation by means of optical microscopy (metallic shiny-non shiny classification). Gravimetry when needed (total particle mass in mg)

Contact us

Call us at (+34) 931 595 691

Alternatively, please fill in the following form, and we will contact you by return.